MFI MFR Tester Machine

Buy Price MFI MFR Test Machine

Melt flow index - MFI Test Machine

Buy MFI MFR Tester, Buy MFI MFR Testing

We offer a wide range of melt flow index (MFI) and melt flow rate (MFR) testing machines designed for high accuracy and durability. Our machines comply with global standards such as ASTM D1238 and ISO 1133, making them ideal for quality control in plastic manufacturing and polymer processing industries.

Reliable MFI & MFR Testing Machines for Plastic & Polymer Industries

We offer a wide range of melt flow index (MFI) and melt flow rate (MFR) testing machines designed for high accuracy and durability. Our machines comply with global standards such as ASTM D1238 and ISO 1133, making them ideal for quality control in plastic manufacturing and polymer processing industries.

Melt Flow Index

MFI testing Machine available Models:

MFI machine model: MTi

MFI Melt Flow Index Device: Model MTi

- Fully compliant with ISO 1133 and ASTM 1238 standards.

Cylinder made of hardened SPK (Grade A). - Display and control of two separate temperature ranges

- Has two separate temperature sensors - Has two separate 500 watt elements

- Equipped with a PID temperature control system and artificial intelligence with self-learning capability for automatic temperature calibration and maximum speed of reaching temperature and temperature equilibrium.

- Equipped with a PWM system to apply controlled input voltage and current to the element to increase element life and minimize damage over time.

- Equipped with a stainless steel rotary cutter with standard or custom cutting time settings. Precise cutting without cutter locking or cutting errors (manual and automatic cutting)

- It has two standard weights (2160 and 5000 grams). Other required weights can be provided as a custom order with the device.

- Stainless steel piston - tungsten carbide die

- The necessary supplies for cleaning the die and cylinder are provided in the box with the machine.

- Ability to apply all user-required settings via the device

- Equipped with a 3.5-inch full-touch color screen

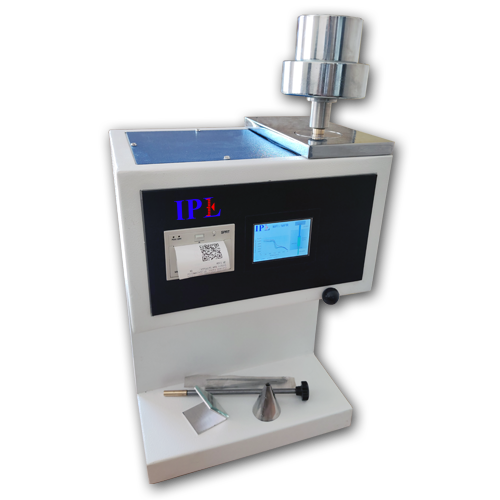

MFI machine model: MTiP

MFI Melt Flow Index Device: Model MTiP

- Fully compliant with ISO 1133 and ASTM 1238 standards

- Cylinder made of hardened SPK (Grade A)

- Display and control of two separate temperature ranges

- Has two separate temperature sensors,

has two separate 500 watt elements - Equipped with a PID temperature control system and artificial intelligence with self-learning capability for automatic temperature calibration and maximum speed of reaching temperature and temperature equilibrium.

- Equipped with a PWM system to apply controlled input voltage and current to the element to increase element life and minimize damage over time.

- Equipped with a stainless steel rotary cutter with standard or custom cutting time settings. Precise cutting without cutter locking or cutting errors (manual and automatic cutting)

- It has two standard weights (2160 and 5000 grams). Other required weights can be provided as a custom order with the device.

- Stainless steel piston

- Tungsten carbide die

- The necessary supplies for cleaning the die and cylinder are provided in the box with the machine.

- Ability to apply all user-required settings via device or computer

- Equipped with a 3.5-inch full-touch color screen,

capable of connecting to a computer via USB port - Special software for Windows (all versions) to provide reports and charts of the tests performed.

- Equipped with a 2-inch thermal printer, thermal label or thermal paper to print test results

MFI machine model: MTiF

MFI Melt Flow Index Device: Model MTiF

- Fully compliant with ISO 1133 and ASTM 1238 standards

- Cylinder made of hardened SPK (Grade A)

- Display and control of two separate temperature ranges

- Has two separate temperature sensors

- Has two separate 500-watt elements

- Equipped with a PID temperature control system and artificial intelligence with self-learning capability for automatic temperature calibration and maximum speed of reaching temperature and temperature equilibrium.

- Equipped with a PWM system to apply controlled input voltage and current to the element to increase element life and minimize damage over time.

- Equipped with a stainless steel rotary cutter with standard or custom cutting time settings. Precise cutting without cutter locking or cutting errors (manual and automatic cutting)

- It has two standard weights (2160 and 5000 grams). Other required weights can be provided as a custom order with the device.

- Stainless steel piston

- Tungsten carbide die

- The necessary supplies for cleaning the die and cylinder are provided in the box with the machine.

- Ability to apply all user-required settings via device or computer

- Equipped with a 3.5-inch full-touch color screen,

capable of connecting to a computer via USB port - Special software for Windows (all versions) to provide reports and charts of the tests performed.

- Equipped with a 2-inch thermal printer, thermal label or thermal paper to print test results

- Equipped with a special 3-zero digital scale built into the device

MFI machine model: MTAi

MFI Melt Flow Index Device: Model MTAi

- Fully compliant with ISO 1133 and ASTM 1238 standards

- Cylinder made of hardened SPK (Grade A)

- Display and control of two temperature ranges and equipped with a new ceramic element

- Has two separate temperature sensors

- Has two separate 1000-watt ceramic elements

- Equipped with a PID temperature control system and artificial intelligence with self-learning capability for automatic temperature calibration and maximum speed of reaching temperature and temperature equilibrium.

- Equipped with a PWM system to apply input voltage to the element to increase the element's lifespan and minimize damage to the element over time.

- Equipped with a rotary cutter with standard or custom cutting time settings. Precise cutting without cutter locking or cutting errors / Possibility to order a non-rotary cutter (manual and automatic cutting)

- It has two standard weights (2160 and 5000 grams). Other required weights can be provided as a custom order with the device.

- 316 stainless steel piston

- Tungsten carbide die

- The necessary supplies for cleaning the die and cylinder are provided in the box with the machine.

- Ability to apply all user-required settings via the device or computer.

Performing all tests fully automatically and independently without the need for an operator (the operator is only responsible for filling the sample tank with the desired material for testing and selecting the type of test). - Equipped with an 8-inch full-touch color screen

- Equipped with a USB port for connecting to a computer and sending test data, and with special software under Windows (from Windows 7 onwards) for printing test reports and charts.

- Equipped with a 2-inch thermal printer to provide printed reports on adhesive labels or thermal paper.

- The entire test is performed before applying the weight, regardless of the first sample exiting the die, and the test result is presented completely automatically, without the need for any action from the operator.

- Equipped with a precise MFI measurement system without the need for scales, operator intervention, etc.

- Equipped with an automatic weight application system from 2,160 to 21 kg, applying real weight without using the ball screw system that was used in older models and caused problems and deviations in the test results.

- Has a cylinder tilting mechanism up to 75 degrees for easy cylinder cleaning.

MFI machine model: MTA

MFI Melt Flow Index Device: Model MTA

- Fully compliant with ISO 1133 and ASTM 1238 standards

- Cylinder made of hardened SPK (Grade A)

- Display and control of two temperature ranges and equipped with a new ceramic element

- Has two separate temperature sensors

- Has two separate 1000-watt ceramic elements

- Equipped with a PID temperature control system and artificial intelligence with self-learning capability for automatic temperature calibration and maximum speed of reaching temperature and temperature equilibrium.

- Equipped with a PWM system to apply input voltage to the element to increase the element's lifespan and minimize damage to the element over time.

- Equipped with a rotary cutter with standard or custom cutting time settings. Precise cutting without cutter locking or cutting errors / Possibility to order a non-rotary cutter (manual and automatic cutting)

- It has two standard weights (2160 and 5000 grams). Other required weights can be provided as a custom order with the device.

- 316 stainless steel piston

- Tungsten carbide die

- The necessary supplies for cleaning the die and cylinder are provided in the box with the machine.

- Ability to apply all user-required settings via the device or computer.

Performing all tests fully automatically and independently without the need for an operator (the operator is only responsible for filling the sample tank with the desired material for testing and selecting the type of test). - Coolant injection after testing to prepare and perform the next test in less than 2 minutes

Designed and built for large companies that need to perform non-stop and fast testing for a large number of samples during work shifts. Capable of continuous and uninterrupted operation - Equipped with a 5-inch full-touch color screen

- Equipped with a USB port for connecting to a computer and sending test data, and with special software under Windows (from Windows 7 onwards) for printing test reports and charts.

- Equipped with a 2-inch thermal printer to provide printed reports on adhesive labels or thermal paper.

- The entire test, from pre-applying the weight, cleaning after the test, pouring the sample into the cylinder, regardless of the first sample exiting the die, weighing the necessary samples, and presenting the test results, is completely automatic and requires no action from the operator.

- The device has a sensor for measuring the weight of samples with an accuracy of 0.001 grams.