Laser Marking for Polyethylene Pipe

Laser marking for polyethylene pipes and laser marking for irrigation tape - Laser marking production line - Laser marking products

The latest polyethylene pipe laser marking and tape laser engraving with the most advanced technology in the world

Free consultation on choosing the right model based entirely on the product and production line conditions.

Laser marking polyethylene pipes

- 1 year warranty and 10 years after-sales service

- Engrave realtime date and time, product specifications, production shift, Batch and Lot number, custom increasing or decreasing numbers and other desired information based on customer needs

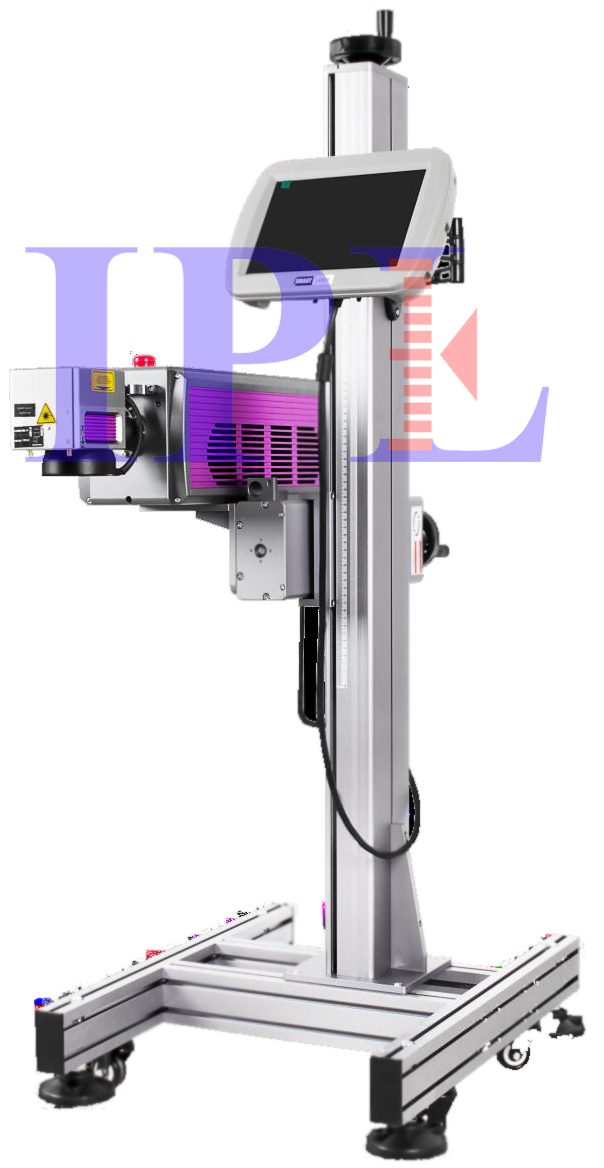

- Available in 20W, 30W, 35W and 50W laser powers

- Extremely high speed of the device with a maximum marking speed of 200 meters per minute

- No consumable parts and maintenance free, No periodic maintenance or replacement

- Available in 4 different models

- D type fiber laser source (up to 100,000 Hours laser source life time)

- Option for Connect to production line automation system (if applicable)

- No special installation or base needed, will ready to use just in 10 minutes.

- Availability of all required spare parts in the company's warehouse and delivery within 24 hours after notification of the need

- No infrastructure changes needed.

Laser marking irrigation tape / laser marking of drip irrigation tape

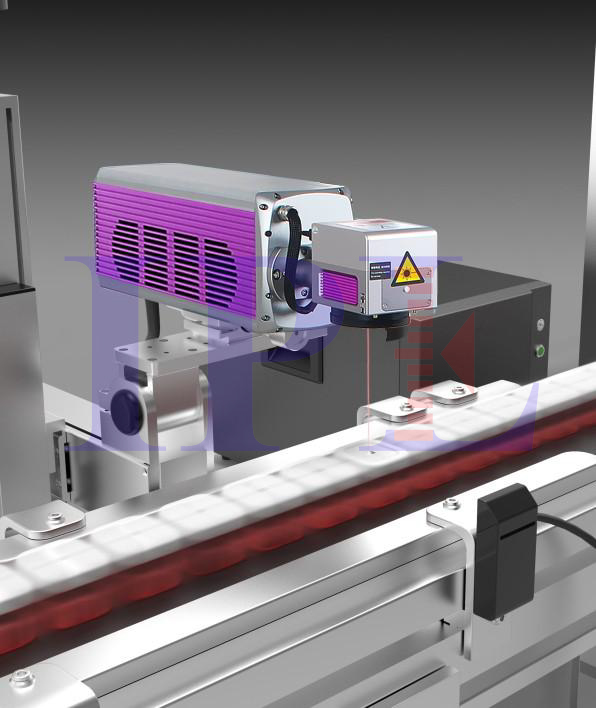

Laser marking production line

This laser system is used to insert information including production and expiration dates, product serial numbers, production batches, shifts, etc., along with the manufacturer’s logo and other desired or required and necessary items on each product. This system has the ability to insert serial numbers automatically and arbitrarily by increasing or decreasing the number for each product or the required combination of numbers and letters. The engraving depth and the amount of laser radiation penetration on the product packaging or the product itself are fully adjustable.

A model of this system has the ability to focus on products that are not the same height on the production line. For example, consider a cake production line, each packaging of which has a specific height. The most important advantage of laser-engraved information on products is that it cannot be erased and re-engraved by profit-seeking individuals. Also, through this, the customer will have 100% confidence in the information contained.

The greatest advantage of laser marking products is that the equipment does not require periodic maintenance and service. The useful life of laser sources is over 100,000 hours of operation and generally they do not have any problems with operation over a long period of time.

The absence of failure of this equipment will ensure that the manufacturer will not experience any interruptions in the production line due to problems related to data entry.